Many PCBA assembly factories usually meet one same problem-Dirty stencil clean!This a simple thing but really headachy.

Cut the cackle,Today I will introduce three ways for cleaning SMT stencil:

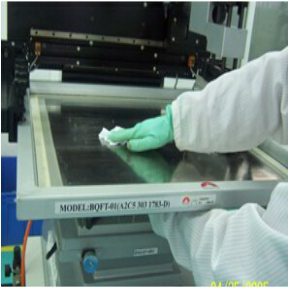

1.Manually soak:

Tools and materials: Cleaning agent,Duster cloth,Special gloves,Container

Cleaning step:

1)spray cleaning agent on the stencil or soak the stencil in a container for a while(if the solder have condensed into pieces).

2)Putting on gloves and use duster cloth to swab down the dirty part with solder paste.

3)Drying by compressed air

4)checking:

2.Pneumatic spray cleaning

Tools and materials: Pneumatic stencil cleaning machine,Cleaning agent,Special gloves

Cleaning Step:

1)Starting air compressor

2)Setting up the cleaning time,drying time

3)Put in stencil and leave to do other work

4)Get stencil out after coming back and put in another one

3.Ultrasonic cleaning

Tools and materials:Ultrasonic stencil cleaner machine,Cleaning agent

Cleaning Step:

1)power on

2)Put in stencil and setting cleaning time and drying time

3)Get stencil out and put in another one

Compare the three ways:

Manually soak:

Advantage:

1)Low-cost

2)Visualization

Disadvantage:

1)Long tine,low-effective

2)High salary cost

3)Cleaning effect is not very good

4)May hurt stencil

Pneumatic spray cleaning:

Advantage:

1)Pneumatic,Automatic,without power

2)High-effective

3)Cleaning effect is good

4)Economize manpower

Disadvantage:

1)Can’t cleaning oversized stencil

2)Cleaning effect is not good with thick stencil

3)Need certain cost to buy machine

Ultrasonic cleaning

Advantage:

1)Automatic

2)High effective

3)Cleaning effect is good

Disadvantage:

1)Need one stuff cooperate

2)High cost

3)Can’t cleaning oversized stencil