Frontline PCB Solutions, an Orbotech-Mentor Graphics company, today announced the launch of InCAM Flex, a dedicated new CAM solution for flex and rigid-flex PCB makers. InCAM Flex combines analysis and editing capabilities with automatic production data optimization to perform high-precision CAM tooling for flex and rigid-flex manufacturing, helping manufacturers meet the challenges of flex PCB production by maximizing their capabilities and flex processes.

"Flex circuit makers are looking to expand their capacity and enhance their processes to meet the increasing demands and challenges of a rapidly growing flex PCB market," said Yovav Sameah, president, Frontline PCB Solutions. "Delivering InCAM Flex to flex manufacturers enables our customers to get the best out of their flex production processes and is the next phase in our strategy to bring our world-leading InCAM capabilities to the entire PCB market."

Frontline PCB Solutions equips PCB shops with a deeply integrated preproduction software experience. InCAM®Flex for CAM and InPlan Flex for Engineering work seamlessly to integrate data flow between front-end departments, resulting in smooth and efficient time-saving interactions and processes.

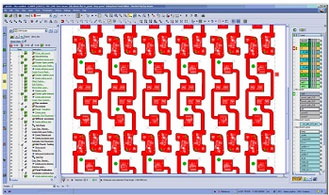

InCAM Flex provides fast, high-precision CAM tooling for flex and rigid-flex manufacturers and enables automatic production data optimization via flex design for manufacturing tools. Combined with powerful flex CAD tools and automatic flex board panelization, InCAM Flex brings with it benefits that are most important for businesses ‒ increasing yields and achieving faster job turnaround. In addition, InCAM Flex seamlessly integrates and shares information with InPlan®Flex Engineering Suite, design and assembly via ODB++, and has a streamlined user interface.